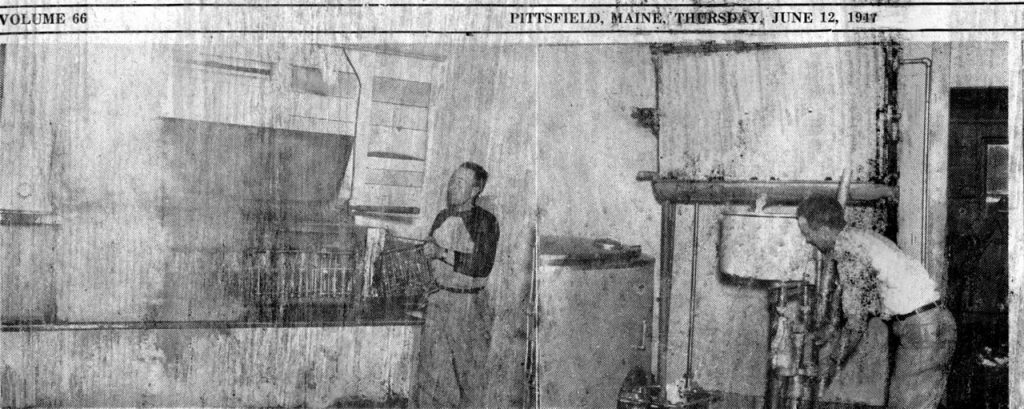

The two pictures above were taken at the new Wright’s manufacturing plant on Somerset Avenue, Pittsfield. The picture on the left shows Lawrence Wright putting bottles into the large container that washes them by a method of steam. The picture on the right shows some of the new equipment in the process of pasteurizing milk. The large vat at the left of the picture holds 625 qts. of raw milk, which then leaves through a pipe and flows over a system of pipes, which can be seen at the very top. When the milk leaves the vat, it is 142 degrees and through a process of ice old water in the system of pipes, the milk is cooled to 42 degrees. The milk can be seen flowing into another container which from there is automatically bottled and capped, and ready for delivery.

WRIGHT’S DAIRY OPENS

MODERN PASTEURIZATION

PLANT ON SOMERSET AVE.

First To Be Put Into Operation By Any Of Town’s

Leading Dairies New One Story Building Houses

Latest Equipment Ninety Percent Of Milk Custom-

ers Have Already Changed To New Form Of Milk

A new modern pasteurization plant was opened the first of this week by Wright’s Dairy. The plant is located in a new one story building just off upper Somerset Avenue, and is the first of its kind to be used by any of the town’s leading dairies. It is operated by Lawrence Wright in conjunction with his father, Harry Wright.

The pasteurization plant actually opened with the first of the month but it was not until this week that operations reached full scale. It was necessary to introduce the new form of milk to the regular milk customers and Lawrence Wright said that now about ninety per cent of his customers are using pasteurized milk and many are going out of their way to tell him how well they like it.

The process of pasteurizing milk is relatively a simple procedure. The raw milk, most of which is obtained from the Wright’s farm on the Hartland road, is poured into a large vat. Here it is heated to a temperature of 142 degrees and is kept at that temperature for thirty minutes.

While being heated, two thermometers are used to check the temperatures. One records it on a chart that is sent to the State Board of Health while the other is used to give a positive check, on the first one.

After being heated for thirty minutes the milk enters a sanitary pump and goes to a surface cooler. This cooler is a system of winding pipes that circulate ice cold water. As the milk flows over these pipes it is cooled from 142 degrees to 42 degrees and at this latter temperature is bottled and stored in a refrigerator.